OTR Tires

E2C® solutions can improve performance in a variety of off-the-road (OTR) tire types and can help tire manufacturers to achieve sustainability goals.

The formulation of tread compounds is one of the most important considerations in OTR tire design as it can affect the overall ability of the tire to resist abrasion, cutting and tearing; to minimize hysteresis (energy loss) and improve fuel economy; and to grip the road and handle responsively.

E2C® solutions have been shown to break critical trade-offs in OTR tire design by both lowering operating temperatures and extending the life of tires for more efficient operation. In addition, because tires made with E2C® solutions last longer and are more energy efficient, raw material consumption and CO2 emissions are reduced and fewer end-of-life tires are generated.

Earthmover

Earthmover tires must perform in a wide range of severe operating environments. These environments require tires with high abrasion resistance and the ability to resist damage from cutting, chipping or chunking from rough/uneven surfaces. In addition, large OTR tires require rubber compounds that minimize hysteresis to reduce failure due to excessive heat build-up.

Aero

Aero tires have unmatched expectations for safety and low mass. Rapid heat buildup and thermal cycling occurs more in aviation applications than anywhere else. Extending the life of tires in these environments means less downtime and lower operating costs for end customers.

Agriculture

Agriculture tires often must survive harsh cut and puncture requirements. Solutions that can reduce early life failures while enabling advanced tire design due to superior compound properties can play a key role in improving customer satisfaction and outcomes. In fact, recent advances in the design of agricultural tires have been proven to improve crop yields.

Port and Industrial

Port and industrial tires are responsible for moving vast amounts of goods for customers where uptime and long life are a priority. Balancing needs between tread durability and heat buildup are essential to delivering the best customer experience in these applications.

Retread

Retreads can extend OTR tire life while reducing the number of waste tires generated – a key benefit for mining operators challenged with optimizing their haulage operations for productivity while reducing costs and improving the environmental footprint of their operations.

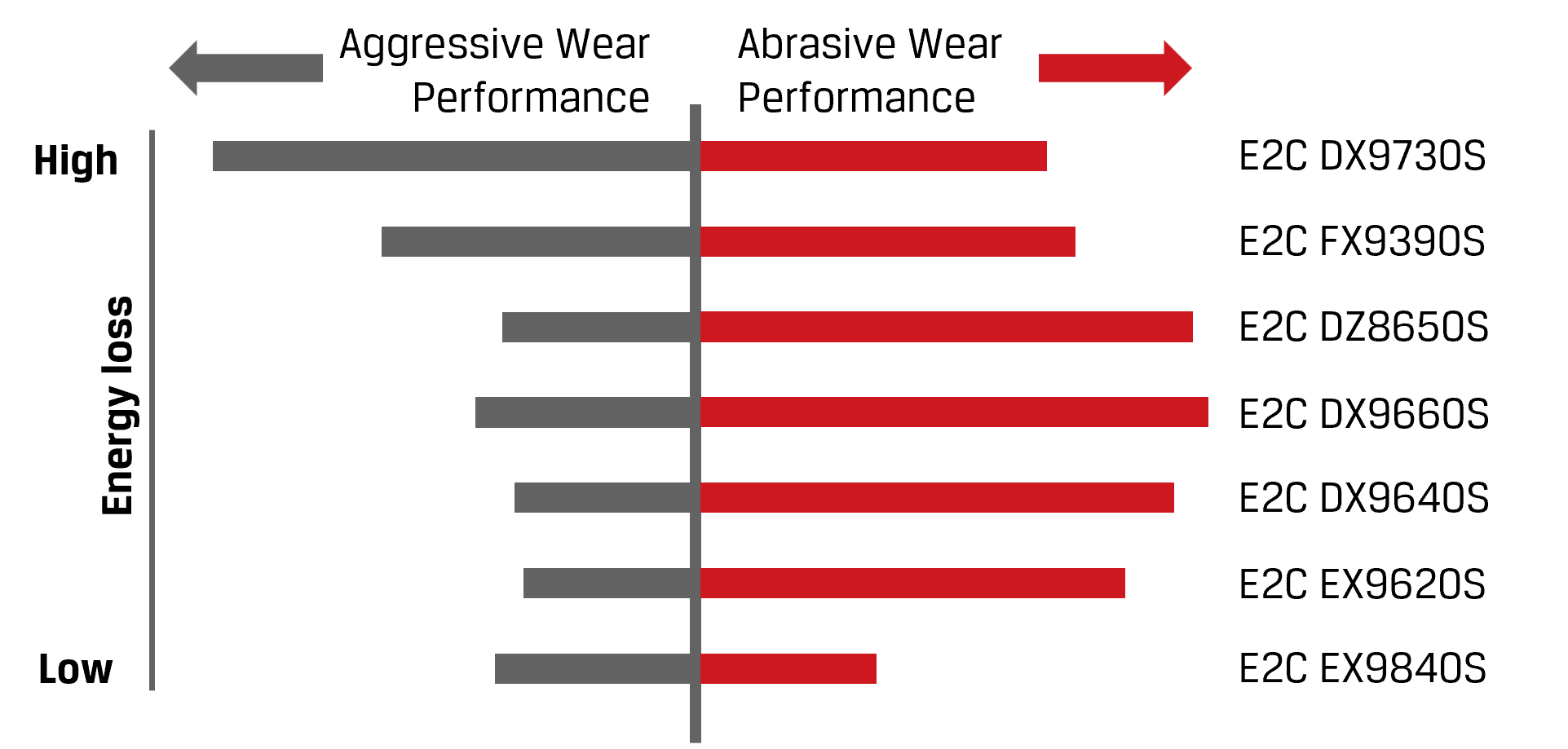

Which E2C® ENGINEERED ELASTOMER COMPOSITE IS RIGHT FOR YOU?

Cabot’s E2C® elastomer composites offer customers a variety of ways to solve their most difficult tread design challenges for OTR and TBR applications:

- EX9840S is designed for applications requiring ultra-low hysteresis and ultra-low heat build up.

- EX9620S and DX9640S are best deployed in high heat buildup applications to extend tread life without impacting wear performance.

- FX9390S allows customers to balance durability and heat buildup performance, while offering flexibility in final compound design.

- DX9660S delivers high abrasion resistance for leading durability performance in on-road commercial vehicle tire treads and protective rubber liners for industrial equipment.

- DX9730S brings extreme durability performance in aggressive wear applications.

- DZ8650S is optimized for OTR tread and retread applications that require high durability.

E2C® DX9730S elastomer composite brings extreme durability performance in aggressive wear applications.

E2C® DX9640S elastomer composite is best deployed in high heat buildup applications to extend tread life without impacting wear performance.

Let's Connect

Please get in touch to order samples of our products or discuss with our technical team to find the best solution for your needs.

Contact Us

Application Guide

eApplication Guide: E2C® Engineered Elastomer Composites for OTR Mining Tire Applications

Download

Application Brief

Application Brief: E2C® Engineered Elastomer Composites for OTR Mining Tire Retread Applications

Download