Special Polymers

Certain industrial rubber product applications require the use of special and relatively expensive polymers like fluoroelastomers (FKM), hydrogenated nitrile butadiene rubber (H-NBR), ethylene acrylate rubber (ACM/EAM) or epichlorohydrine rubber (ECO).

Rubber applications that require these special polymers often do not allow for a higher compound extension with plasticizer or white fillers due to aging or compression set restrictions. For these special compounds, SPHERON® 4000 and STERLING® 1120 carbon blacks offer higher loading capability when compared to ASTM N700, 600 and 500 series carbon blacks, while providing acceptable reinforcement properties. Our carbon black products can help control compound and rubber part costs for applications that require the use of special and relatively expensive polymers.

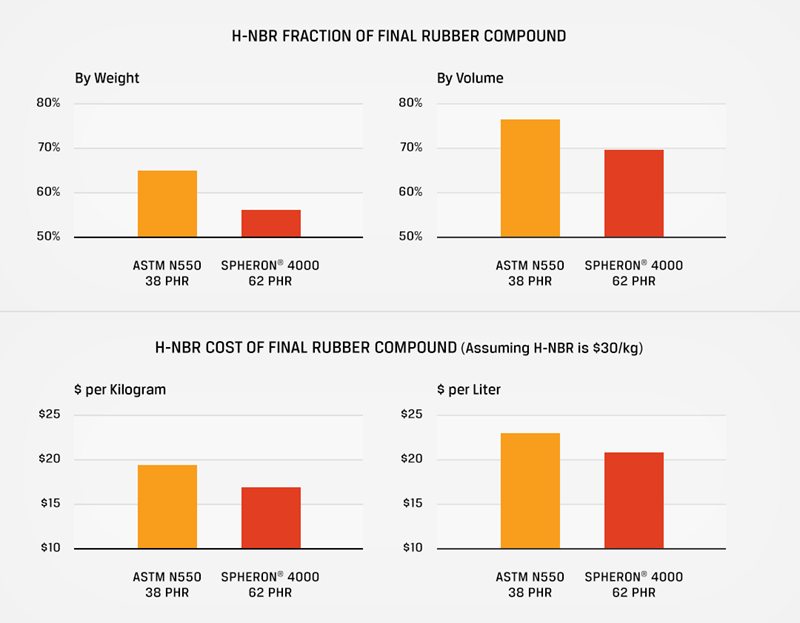

SPHERON® 4000 Carbon Black versus ASTM N550

Special polymer systems can prove expensive and, at times, cost prohibitive. Fortunately, using carbon blacks at a very high PHR loading, as detailed below, can help streamline expenditures and control overall production costs. SPHERON 4000 carbon black is a premium, high-performing product that effectively reduces the total amount of special polymers needed for production, thereby reducing overall throughput expenses.

The charts below represent the potential cost savings of SPHERON 4000 carbon black as compared to ASTM N550 carbon black in an H-NBR polymer-based timing belt formulation. The considerably higher PHR loading for SPHERON 4000 carbon black enables a significant reduction H-NBR polymer costs in the rubber compound.