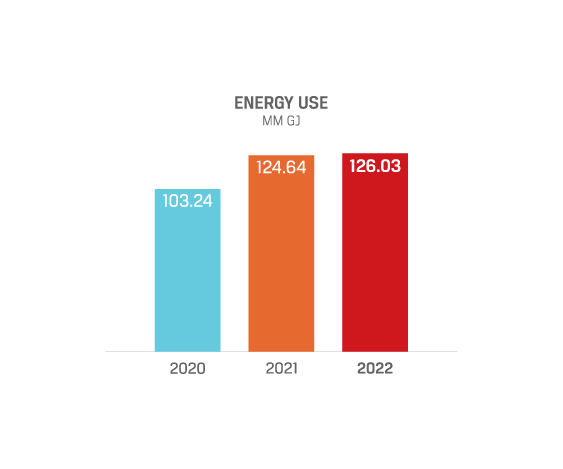

Energy

Our focus on energy is consistent with our corporate strategy to generate value through efficiency and optimization.

We understand that improved energy efficiency delivers both direct and indirect emission reduction and economic benefits. Our manufacturing processes are heavily dependent on energy, and we are committed to continuously looking for ways to advance toward our goal of reducing our overall energy intensity by reducing our consumption and harnessing waste energy often lost in our processes.

We have reached an important milestone in our 2025 goal of exporting 200% of the energy we import, achieving a new record amount of energy exports and imported energy per ton of product. As a result, in 2022 we achieved an energy ratio of 214%, exceeding our target of 200%. This accomplishment is the outcome of our actions to improve energy efficiency and proactively invest in energy recovery systems, which make our facilities energy self-sufficient and net exporters to nearby businesses and communities.

Energy recovery and energy efficiency continue to be two important focus areas of our environmental strategy while we explore new opportunities to innovate and invest in lower-carbon production processes.

We recently completed two projects in China supporting our energy export ratio goal. At our Xingtai, China facility we completed the installation of a new water-cooling condensing system as part of the energy recovery process. This investment allows for the use of hot water in the local community by supplying about 290 terajoules (TJ) of energy per year. At our Tianjin, China carbon black facility we upgraded our energy recovery system with a new steam turbine enabling us to increase our electricity and steam production that is sent to an adjacent neighborhood and industrial park that is used for their heating purposes.

Our Ravenna, Italy site is one of our 13 locations that converts waste heat into useful energy through local partnerships. As of 2022, when compared to our 2005 baseline, our energy center investments have enabled our energy customers to avoid approximately 497,000 MT of greenhouse gas emissions.

Performance

View our latest sustainability report to learn about our progress and goals.

Download Here